630KG 8 Persons Passenger Lift Elevator e nang le moralo o tloaelehileng

Lintlha mabapi le Shanghai Fuji Elevator Co.,Ltd

Shanghai FUJI Elevator Co., Ltd.e simolohile ka 1985 ke karolo ea sehlopha se seholo haholo, da hai holding,ke lekhetlo la pele la naha la AA level professional elevator production,installation,modifocation,maintenance license.Located in no.299 baofeng road,xuxing town,jiading district,Shanghai,the company is setsi sa ntlo-khōlō se kopanya lifti, escalator, lisebelisoa tsa ho paka tsa mochini R&D, tlhahiso, papatso, pontšo le koetliso. Khamphani e na le setsi sa ponts'o se felletseng sa lihlahisoa le setsi sa boiphihlelo ba bareki, 4.0 molemong oa boemo bo tsoetseng pele ba indasteri ba mela ea tlhahiso e ikemetseng, lifiti tse inehetseng tekong. lisebelisoa le setsi sa ho hlahloba lintlha tsa Inthanete, boleng le ts'ebetso ea ts'ireletso ea lifti e fana ka tiisetso e ka tšeptjoang. Tora ea liteko ea sejoale-joale ea 108-meter e fetohile letšoao la bohlokoa sebakeng seo. Khamphani e ka hlahisa lihlahisoa tse fihlang ho 10000 tsa tlhahiso ea selemo le ho fana ka tharollo e pharaletseng ea lifti bakeng sa lipalangoang tse mahlakore a mararo tsa meaho e fapaneng.

Theknoloji ea mantlha ea lifti ea FUJI e tsoa Japane, ka boqapi bo felletseng ba tekheniki, e ntlafatsa ho kopanngoa ha lisebelisoa tsa indasteri ea lifti ea lefats'e, mme e theha ka botlalo lihlahisoa tsa lifti tse fihlelang litlhoko tsa 'maraka o bohareng le o holimo. tšebelisano 'moho le univesithi ea Shanghai Jiaotong le setsi sa bochabela sa China sa mahlale le thekenoloji,' me se etsa lipatlisiso le nts'etsopele ea lifti ea theknoloji e phahameng, paballo ea matla le ts'ireletso ea tikoloho le ts'ireletso e phahameng. tlhahlobo eohle ea boleng ba ts'ebetso le likarolo tse ling ho fihlella le ho feta 'maraka oa Europe maemo a tšoanang a lihlahisoa.

Ha ho na molemo ka ho fetisisa, feela molemo ka ho fetisisa.FUJI lifti ke setsebi se hloahloa indastering ea lifofane tsa lefats'e, moetapele oa theknoloji ea polokeho, moetapele oa paballo ea matla le thekenoloji ea ts'ireletso ea tikoloho, le thekenoloji ea theknoloji e phahameng ea litšebeletso tsa batho.

Tlhahisoleseding ya Sehlahiswa

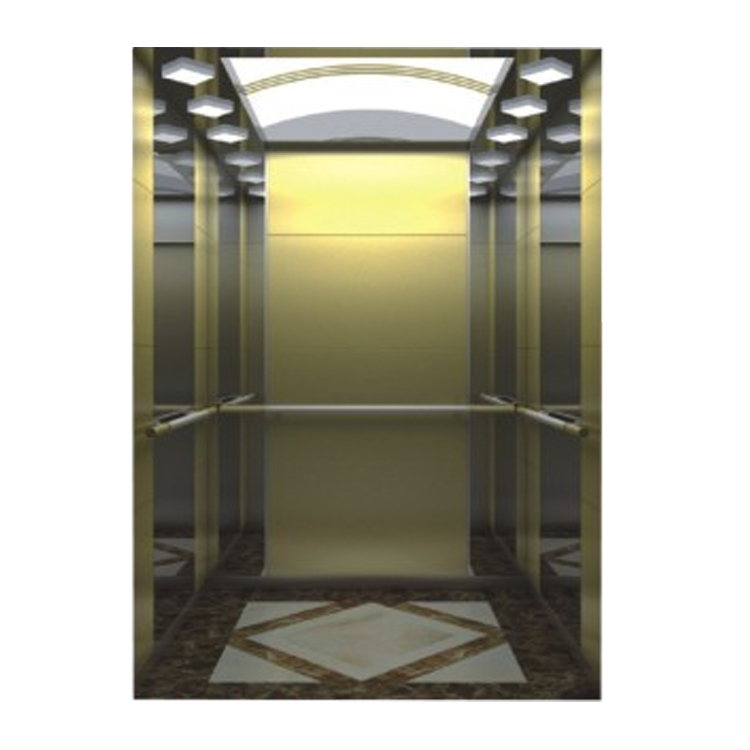

Elevator ea baeti (kamore ea mochini)

Ntle le tsamaiso e sebetsang le ea bohlale, lifti ea kamore ea mochine e nyenyane e boetse e sebetsa mochine o monyenyane oa ho hula le moralo o mosesaane oa khabinete ea taolo, e leng se etsang hore kamore ea mochine e be nyenyane le hore moralo o kopane haholoanyane.Moloko o mocha oa lifti ea kamore ea mochini o monyane e hlile e phethahatsa mohopolo oa k'hamphani oa ho boloka matla.

E boloka sebaka haholo

Kamore ea mochini ke katoloso feela ea seliba.E loketse kahong le ka theko e tlase.Tšebeliso ea mochini oa compact gearless traction o siea sebaka se seholo sa kamore ea mochini.

Elevator ea baeti (Mochini ha o na kamore)

Khampani mochine o se nang kamore ea baeti, ka ho ameha ka tikoloho, o boloka matla le ho fokotsa tšebeliso, ho boloka sebaka sa kaho le ho eketsa bolokolohi ba baqapi, ka hona ho bonahatsa ka botlalo khopolo ea setso se botsoalle sa tikoloho.Ha ho bapisoa le lifensetere tsa li-gearwheel tse nang le boima bo tšoanang ba mojaro, lifti tse se nang mochini li boloka 25% ea motlakase le 10% ea sebaka sa kaho.Khamphani e qhekelletse tlhokahalo ea hore likamore tsa mochini li tlameha ho ba teng bakeng sa lifti, ho fana ka menyetla e se nang moeli ea ho theha sebaka se lekanyelitsoeng sa moaho oa sejoale-joale.

Mokhoa o Felletseng oa Taelo

1. Lintho tse tala

Re hlahloba ka tieo le ho tiisa boleng ba lisebelisoa tse tala.

Lefapha la QC le tla hlahloba lisebelisoa tsohle, ha thepa e tala e fihla fekthering, re hanne lihlahisoa leha e le life tsa cucounterfeit.Ke lisebelisoa tse tšoanelehang feela tse tla kena polokelong ea thepa e tala

.

2. Ho hlahisa tsamaiso

Lefapha la tlhahiso le tla etsa tlhahiso ho latela litaelo tsa enjineri.

Ho na le lenane-thuto kopanong ka 'ngoe e bonts'ang moralo oa tlhahiso letsatsi le letsatsi.Ka tsela ena, basebetsi ba

Bohle ba tseba hantle hore na ke projeke efe e hlahisang hona joale.Ebe u hlahloba boemo ba mechine pele o sebetsa.

3. Ho paka

Re sebelisa plywood e tiileng e ka emang nako e telele ka sekepeng sa leoatle.Bakeng sa likarolo tse ling tsa bohlokoa, joalo ka khabinete ea taolo,

Mokhanni oa monyako le motlakase, likarolo li tla koaheloa ke filimi e matla pele, e nang le desiccant, pele e kenngoa ka mabokoseng.

4. Taolo ea Boleng

1) Lisebelisoa tsohle tse tala li tla hlahlojoa pele li kena ka tlung ea polokelo.'Me lihlahisoa tsa elektroniki tse ngata li etsa tlhahlobo ea sampole.Likarolo tsohle li tlameha ho ba le setifikeiti se tšoanelehang ho tsoa ho barekisi

Mosebetsi1 o ikarabella ho sena.

2) Kamora hore lifti le litepisi li qete, Re tla leka papali ea enjene ea lifti le khabinete ea taolo, le boemo ba ho matha ha litepisi le maoto a tsamaeang.

3) Basebeletsi ba tla kenya likarolo tse ling tsa mantlha pele ba paka, joalo ka kh'abin / lebone la motlakase, haeba lesoba le sa nepahale.

4) Kamora ho paka, re tla hlahloba boemo ba sephutheloana bakeng sa likarolo ka 'ngoe, ebe re nka foto bakeng sa litšupiso tse ling.

5) Ha ho pepa, re tla hlahloba hore na likarolo tsohle li tletse ka setshelo ho qoba ho haella, 'me re nke linepe bakeng sa litšupiso tse ling.

5. Ka mor'a Tšebeletso ea Thekiso

1) Fana ka tlhokomelo ho moemeli oa lehae.

2) E hlophisitsoeng ke moreki.

3) Haeba ho hlokahala, re fana ka koetliso bakeng sa bareki.

4) Re hlophisa basebetsi ba litsebi bakeng sa ho kenya le ho romelloa.Empa moreki o hloka ho re tsebisa khoeli e 1 esale pele bakeng sa visa.

Mosebetsi o ka sehloohong

| Mosebetsi o tloaelehileng | ||||

| 1 | Ts'ebetso ea ho hlahloba | 29 | Tšireletso e fetang lebelo | |

| 2 | Ho matha butle | 30 | Tšireletso ea ho kopana bakeng sa li-switches tsa mariki | |

| 3 | Tokiso ea nako ea ho bula lemati e ikemetseng | 31 | Puisano ka mehala | |

| 4 | Phallo e felletseng ea mojaro | 32 | Tšireletso ea mabili | |

| 5 | Ho itima mabone le monate | 33 | Tseko ea alamo | |

| 6 | Ho khutlela hae ka tsela e iketsang | 34 | Mabone a tshohanyetso | |

| 7 | Ho koala lemati hape | 35 | Tšireletso ea phetoho ea boemo | |

| 8 | Phoso ea ho rekota | 36 | Ho hlakolwa ha mehala e fosahetseng | |

| 9 | Hoist way self learning | 37 | Ho hlakolwa ha mohala o fetotsweng ka ho iketsa | |

| 10 | Ho bula lemati ka ho iketsa | 38 | Phatlalatso e bonts'ang ho seta ka tsela | |

| 11 | Tšebeletso ea mohlokomeli | 39 | Ho matha ka thoko | |

| 12 | Ts'ebetso ea Bypass | 40 | Letheba la matrix floor indicator | |

| 13 | Tokiso e iketsang ea lets'oao la boemo ba fatše | 41 | Pontšo e potolohang ea tsela e mathang | |

| 14 | Ho notlela ka phahamiso | 42 | KAKA tshireletso ya puisano | |

| 15 | Tšireletso ea ho notlela mamati ka ntle ho sebaka sa monyako | 43 | Ho fihla | |

| 16 | Tšireletso e khanyang ea infrared | 44 | Ho khutla ha tšohanyetso ha ho ka cha | |

| 17 | Tšireletso e fetang mojaro | 45 | Tšireletso ea taolo e ka sehloohong | |

| 18 | Tšireletso ea ho khutlela morao | 46 | Taolo e kholo ts'ireletso ea CPU WDT | |

| 19 | Tšireletso e khahlanong le ho tlōla | 47 | Setulo se ikhethileng sa mokatong oa litšebeletso | |

| 20 | Tšireletso ea li-switches tsa anti terminal | 48 | Ho sebetsa teko | |

| 21 | Anti-terminal holim'a tšireletso e sebetsang | 49 | Taolo ea oache | |

| 22 | Tšireletso ea mantsoe | 50 | Ho theoha ka kotloloho | |

| 23 | Tšireletso ea contactor | 51 | Sesebelisoa sa ho beha boima | |

| 24 | Failure analysis of shaft self learn | 52 | Taolo e kopanetsoeng e felletseng | |

| 25 | Tšireletso ea mocheso oa motlakase | 53 | Konopo ea ho bula lemati (ka ntle) | |

| 26 | Tšireletso ea ho hlōleha ha monyako | 54 | Konopo ea ho bula lemati (ka hare) | |

| 27 | Tšireletso bakeng sa senotlolo sa lemati se khuts'oane | 55 | Mosebetsi o sebetsang oa mollo | |

| 28 | Ho hloleha ho notlela mamati bakeng sa li-switches tsa mariki | |||

| Mosebetsi oa boikhethelo | ||||

| 1 | Bula lemati esale pele | 10 | Taolo e hole | |

| 2 | Ho paka ka kotloloho | 11 | Mosebetsi oa khamera ka koloing | |

| 3 | Taolo ea sehlopha | 12 | Seboholi sa lentsoe | |

| 4 | Taolo ea Duplex | 13 | Lebokose la ts'ebetso ea mothusi oa koloi | |

| 5 | Ts'ebeletso e phahameng ea mosebetsing | 14 | Lebokose la tšebetso bakeng sa batho ba holofetseng | |

| 6 | Ts'ebeletso e phahameng e sa sebetseng | 15 | Tšebeletso ea ho letsa e bohlale | |

| 7 | Monyako o bulehile nako | 16 | Mosebetsi oa ho laola karete ea IC | |

| 8 | Ho fihla ha koloi | 17 | Ho leka-lekanya ha motlakase o fela | |

| 9 | Remote monitor | |||

| Litlhaloso tsa phahamiso ea baeti ka kamoreng e nyane ea mochini | |||||||||

| No. ea batho | E lekantsoeng ka matla (kg) | Lebelo le lekantsoeng (m/s) | Boholo ba nete ea koloi | Saese ya nete ya mamati(DW*DH)mm | Shaft ka hare ho tekanyo | Boholo ba kamore ea mochini | Bophahamo bo phahameng ba leeto(m) | ||

| W*D(mm) | 2P setsi sa ho bula | W*D(mm) | Botebo ba sekoti | OH | W*D*H(mm) | ||||

| 6 | 450 | 1.0 | 1200*1000 | 700*2100 | 1750*1620 | 1500 | 4400 | 1750*1620*2500 | 45 |

| 8 | 630 | 1.0 | 1400*1100 | 800*2100 | 2000*1720 | 1500 | 4400 | 2000*1720*2500 | 45 |

| 1.6/1.75 | 1600 | 4500 | 96 | ||||||

| 10 | 800 | 1.0 | 1400*1350 | 800*2100 | 2000*2000 | 1500 | 4400 | 2000*2000*2500 | 45 |

| 1.6/1.75 | 1600 | 4500 | 96 | ||||||

| 2.0 | 1800 | 4900 | 120 | ||||||

| 2.5 | 2000 | 5100 | 150 | ||||||

| 13 | 1000 | 1.0 | 1600*1500 | 900*2100 | 2200*2150 | 1500 | 4400 | 2200*2150*2500 | 45 |

| 1.6/1.75 | 1600 | 4500 | 96 | ||||||

| 2.0 | 1800 | 4900 | 120 | ||||||

| 2.5 | 2000 | 5100 | 150 | ||||||

| 3.0 | 2600 | 5600 | 150 | ||||||

| 3.5 | 3100 | 5950 | 180 | ||||||

| 4.0 | 3850 | 6350 | 180 | ||||||

| 15 | 1150 | 1.0 | 1700*1500 | 1000*2100 | 2300*2200 | 1500 | 4400 | 2300*2120*2500 | 45 |

| 1.6/1.75 | 1700 | 4500 | 96 | ||||||

| 2.0 | 1800 | 4900 | 120 | ||||||

| 2.5 | 2000 | 5100 | 150 | ||||||

| 3.0 | 2600 | 5600 | 150 | ||||||

| 3.5 | 3100 | 5950 | 180 | ||||||

| 4.0 | 3850 | 6350 | 180 | ||||||

| 16 | 1250 | 1.0 | 1950*1400 | 1100*2100 | 2550*2100 | 1500 | 4400 | 2600*2100*2500 | 45 |

| 1.6/1.75 | 1700 | 4500 | 96 | ||||||

| 2.0 | 1800 | 4900 | 120 | ||||||

| 2.5 | 2000 | 5100 | 150 | ||||||

| 3.0 | 2600 | 5600 | 150 | ||||||

| 3.5 | 3100 | 5950 | 180 | ||||||

| 4.0 | 3850 | 6350 | 180 | ||||||

| 18 | 1350 | 1.0 | 1950*1500 | 1100*2100 | 2550*2250 | 1500 | 4400 | 2600*2200*2500 | 45 |

| 1.6/1.75 | 1700 | 4500 | 96 | ||||||

| 2.0 | 1800 | 4900 | 120 | ||||||

| 2.5 | 2000 | 5100 | 150 | ||||||

| 3.0 | 2600 | 5600 | 150 | ||||||

| 3.5 | 3100 | 5950 | 180 | ||||||

| 4.0 | 3850 | 6350 | 180 | ||||||

| 21 | 1600 | 1.0 | 1950*1750 | 1100*2100 | 2550*2500 | 1500 | 4400 | 2600*2500*2500 | 45 |

| 1.6/1.75 | 1700 | 4500 | 96 | ||||||

| 2.0 | 1800 | 4900 | 120 | ||||||

| 2.5 | 2000 | 5100 | 150 | ||||||

| 3.0 | 2600 | 5600 | 150 | ||||||

| 3.5 | 3100 | 5950 | 180 | ||||||

| 4.0 | 3850 | 6350 | 180 | ||||||

Tlhokomeliso: tafole ea paramente e bonts'a moralo o tloaelehileng oa lifti ea baeti ea kamore ea rona e nyane.Hape re ka u etsetsa lifti ka parameter ea hau.

Khamphani e nang le boiphihlelo e amohelang lifti e sebetsa joalo ka barekisi / moemeli oa rona ho sebelisana le rona ka nako e telele.Re ka thabela ho fana ka theko ea rona ea papatso ea morekisi / moemeli e le moputso bakeng sa tšebelisano.haeba u thahasella, ka kopo u se ke ua tsilatsila ho ikopanya le rona.Kea leboha!