Massive Selection for Heavy Lift Garage Elevator - Machine Roomless 13 Passenger Elevator 1250kg Lift Size – Fuji

Massive Selection for Heavy Lift Garage Elevator - Machine Roomless 13 Passenger Elevator 1250kg Lift Size – Fuji Detail:

Company Information About Shanghai Fuji Elevator Co.,Ltd

Shanghai FUJI Elevator Co.,Ltd. originated in 1985 belong to the very large group,da hai holding,is the first national AA level professional elevator manufacturing,installation,modifocation,maintenance license.Located in no.299 baofeng road,xuxing town,jiading district,Shanghai,the company is the headquarters center integrating elevator,escalator,mechanical parking equipment R&D,production,marketing,display and training.The company has a professional comprehensive product display and customer experience center,4.0 on behalf of the industry’s advanced level of automated production lines,elevators dedicated test facilities and Internet data monitoring center,the quality and safety operation of the elevator provides a reliable guarantee.The 108-meter modern test tower has become a landmark in the area.The company can produce up to 10000 sets of annual production capacity,and provide a comprehensive elevator solution for the three-dimensional transportation of various buildings.

FUJI elevator core technology originates from Japan,through the comprehensive technical innovation,optimizes the integration of the global elevator industry resources,and fully creates the elevator products that meet the needs of the middle and high-end market.At home,the company has specialized cooperation with Shanghai Jiaotong university and east China institute of science and technology,and carries out professinal research and development in elevator high-tech,energy conservation and environmental protection and high security.Henk elevator is now in the product design,production,installation and the whole process quality monitoring and other aspects to reach and exceed the European market similar products standard.

There is no best,only better.FUJI elevator is the best practitioner in the global elevator industry ,the leader in safety technology,the leader in energy conservation and environmental protection technology,and the technology of high-tech humanization service technology.

Product Information

Passenger elevator(Machine room)

Apart from the effective and intellectual control system, the small machine room elevator also applies small traction machine and thin control cabinet design, which make the machine room smaller and the layout more compact. The new generation small machine room elevator truly fulfill the company’s energy-saving concept.

It greatly saves the space

Machine room is only an extension of the well. It is convenient in construction and low in cost. The application of compact gearless traction machine leaves a larger space for machine room.

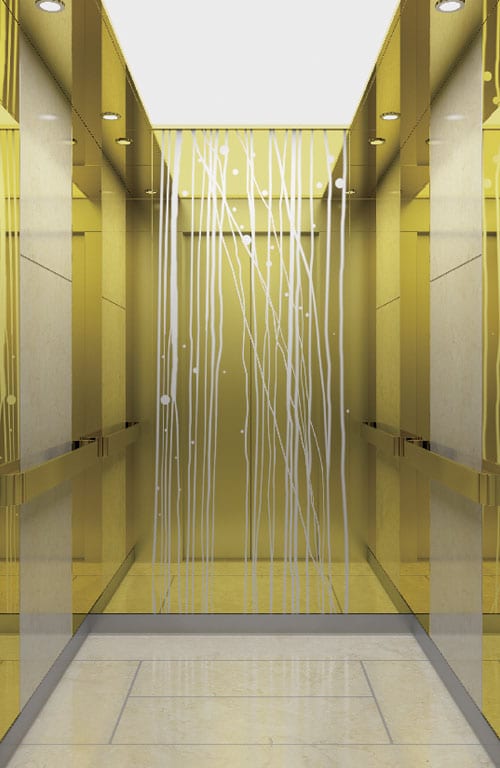

Passenger elevator(Machine roomless)

The company machine roomless passenger elevator, with an environment concern, saves energy and reduces the consumption, save the construction area and increases the freeness of designers, thereby fully reflect the idea of environ ment friendly culture. Compared with the gearwheel elevators with the same load capacity, machine roomless elevators save 25% electricity and 10% of construction area. The company has broken through the prerequiste that machine rooms must be available for elevator, providing limitless possibilities of creation for the limited space of modern construction

A Complete Order Process

1. Raw Material

We stictly check and contol the quality of raw materials.

QC department will check all the materials, when raw material comes to factory, we refused any cuounterfeit products. Only qualified material will get into raw material warehouse

.

2. Producing management

Production department will make the production according to enginner’s instrution.

There is a agenda in each workshop showing the production plan everyday. By this way, The workers are

All clearly know which project is producing now. Then check the machines status before operation.

3. Packing

We apply solid plywood which can stand long time sea shipping. For some important parts, like control cabinet,

Door operator and motor, parts will be covered by a strong film first, with desiccant, before put into boxes.

4. Quality Control

1) All raw materials will be checked before get into warehouse. And bulk electronic product do sampling inspection. All parts must have qualified certificate from suppliers

Worker1 is responsible for this.

2) After elevator and escalator finished, We will test the match of elevator motor and control cabinet, and the running condition of escalator and moving walks.

3) Workers will install some main parts before packing, such as cabin/supporting beam of motor, in case any hole is not accurate.

4) After packed, we will check package condition for each parts, and takes photo for further reference.

5) When delivery, we will check if all parts packed in container to avoid any missing, and take photos for further reference.

5. After Sales Service

1) Entrust maintenance to local agent.

2) Arranged by customer.

3) If necessary, we provide training for customer.

4) We arrange professtional workers for installation and commision. But buyer need to inform us 1 month advance for visa.

Main function Standard function

1 Inspection operation

29 Over speed protection

2 Slow speed running

30 Contact protection for brake switches

3 Automatic door opening time adjustment

31 Interphone communication

4 Full load bypass

32 Wheeling protection

5 Automatic turn off lighting and fun

33 Alarm bell

6 Automatic return to home landing

34 Emergency lighting

7 Door re-closing

35 Level switch protection

8 Error recording

36 False call canceling

9 Hoist way self learning

37 Automatic reversal call canceling

10 Automatic door opening

38 Floor display directional setup

11 Attendant service

39 Isolate running

12 Bypass operation

40 Dot matrix floor indicator

13 Automatic correction of floor position signal

41 Rolling display of running direction

14 Lift locking

42 CAN communication protection

15 Protection of door lock up outside dooor area

43 Arrival gong

16 Infrared light curtain protection

44 Emergency return in case of fire

17 Over load protection

45 Main control protection

18 Reversal runing protection

46 Main control CPU WDT protection

19 Anti-skip protection

47 Discretional setup of service floor

20 Anti terminal switches protection

48 Test running

21 Anti-terminal over running protection

49 Clock control

22 Phrase protection

50 Direct landing

23 Contactor protection

51 Load weighting device

24 Failure analysis of shaft self learn

52 Full collective control

25 Motor temperature protection

53 Door opening button (external)

26 Door opening failure protection

54 Door opening button (internal)

27 Protection for door lock short circuit

55 Fire running function

28 Door lock failure for brake switches

Optional function

1 Open the door in advance

10 Remote control

2 Direct parking

11 Camera function in the car

3 Group control

12 Voice announcer

4 Duplex control

13 Car assistant operation box

5 On-duty peak service

14 Operation box for the handicapped

6 Off-duty peak service

15 Intelligent calling service

7 Door open time extending

16 IC card control function

8 Car arrival gong

17 Leveling when power failure

9 Remote monitor

Small machine room passenger lift specifications

No. of persons Rated capacity

(kg) Rated speed (m/s) Car net size Door net size(DW*DH)mm Shaft inside dimension Machine room size Max traveling height(m)

W*D(mm) 2P center opening W*D(mm) Pit depth OH W*D*H(mm)

6 450 1.0 1200*1000 700*2100 1750*1620 1500 4400 1750*1620*2500 45

8 630 1.0 1400*1100 800*2100 2000*1720 1500 4400 2000*1720*2500 45

1.6/1.75 1600 4500 96

10 800 1.0 1400*1350 800*2100 2000*2000 1500 4400 2000*2000*2500 45

1.6/1.75 1600 4500 96

2.0 1800 4900 120

2.5 2000 5100 150

13 1000 1.0 1600*1500 900*2100 2200*2150 1500 4400 2200*2150*2500 45

1.6/1.75 1600 4500 96

2.0 1800 4900 120

2.5 2000 5100 150

3.0 2600 5600 150

3.5 3100 5950 180

4.0 3850 6350 180

15 1150 1.0 1700*1500 1000*2100 2300*2200 1500 4400 2300*2120*2500 45

1.6/1.75 1700 4500 96

2.0 1800 4900 120

2.5 2000 5100 150

3.0 2600 5600 150

3.5 3100 5950 180

4.0 3850 6350 180

16 1250 1.0 1950*1400 1100*2100 2550*2100 1500 4400 2600*2100*2500 45

1.6/1.75 1700 4500 96

2.0 1800 4900 120

2.5 2000 5100 150

3.0 2600 5600 150

3.5 3100 5950 180

4.0 3850 6350 180

18 1350 1.0 1950*1500 1100*2100 2550*2250 1500 4400 2600*2200*2500 45

1.6/1.75 1700 4500 96

2.0 1800 4900 120

2.5 2000 5100 150

3.0 2600 5600 150

3.5 3100 5950 180

4.0 3850 6350 180

21 1600 1.0 1950*1750 1100*2100 2550*2500 1500 4400 2600*2500*2500 45

1.6/1.75 1700 4500 96

2.0 1800 4900 120

2.5 2000 5100 150

3.0 2600 5600 150

3.5 3100 5950 180

4.0 3850 6350 180

Note: the parameter table shows the standard design of our small machine room passenger elevator. We also can design elevator for you with your parameter.

Welcome experienced elevator company act as our distributors/agent to cooperate with us on long term basis. We would like to provide our distributor/agent promotion price as reward for the cooperation. if you are interested, please do not hesitate to contact with us. Thanks!

Best Rgds.

Sally An Oversea Sales

Shanghai Fuji Elevator Co., Ltd.

ADD:No.528, Shanghai City. China.

Mobile:+86-18018540819

Product detail pictures:

Related Product Guide:

Zozo: The Sunseeker 131 superyacht that cranks up the volume | 12 Person Passenger Elevator

JPS Urged By Contractor Not To Repair Elevators Themselves Days Prior To Nurse’s Injury | Unloading Elevator For Sale

The corporation keeps to the operation concept "scientific management, superior quality and performance primacy, consumer supreme for Massive Selection for Heavy Lift Garage Elevator - Machine Roomless 13 Passenger Elevator 1250kg Lift Size – Fuji , The product will supply to all over the world, such as: Burundi, Palestine, Palestine, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!